The Seal of Approval – First time, Every time.

Food packaging is in the spotlight as rising wholesale gas prices are causing a carbon dioxide shortage in the UK. Food manufacturers around the world typically use carbon dioxide in modified atmosphere packaging (MAP) to increase the shelf-life of products ranging from meat and seafood to cheese, fruit, and baked products. The technology replaces the atmospheric air inside a package with a protective gas mix – including carbon dioxide – to reduce the amount of oxygen and so help the contents stay fresh for as long as possible.

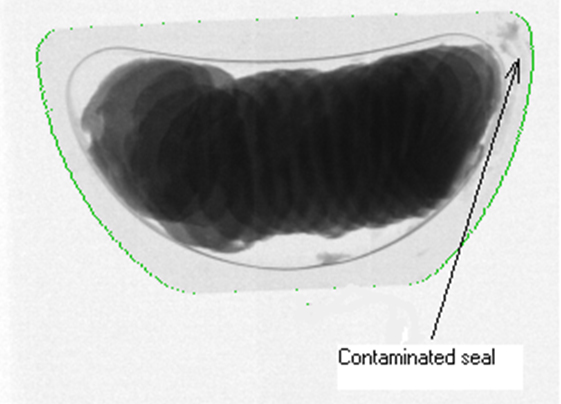

That is why a good seal is so crucial when it comes to food packaging. If a salad leaf gets caught up in the seal and is left sticking out of a packaged pasta salad, for example, it will breach the airtight seal and allow in oxygen – which will make the product spoil faster. This leads to wastage for supermarkets, as shoppers tend to look for the freshest products in a store.

On top of that, if a customer returns a product that has deteriorated before its best-before date, many supermarkets impose a fine on the manufacturer. So food manufacturers feel pressure to get packaging right first time, every time. To alleviate these issues, we decided to create a seal-inspection option for our bestselling G20 x-ray inspection system. This is available on new systems and can also be added onto your existing system.

Traditional Seal Inspection

Traditionally, seal inspection solutions have involved a sniffer approach, to detect nitrogen or carbon dioxide, or a pressure system to check whether a product bounces back or deflates. If it deflates, it gets rejected. Another option is vision systems but their accuracy is limited. All three approaches involve additional machines for manufacturers, with the associated costs in terms of money and factory space.

Benefits of X-ray Seal Inspection

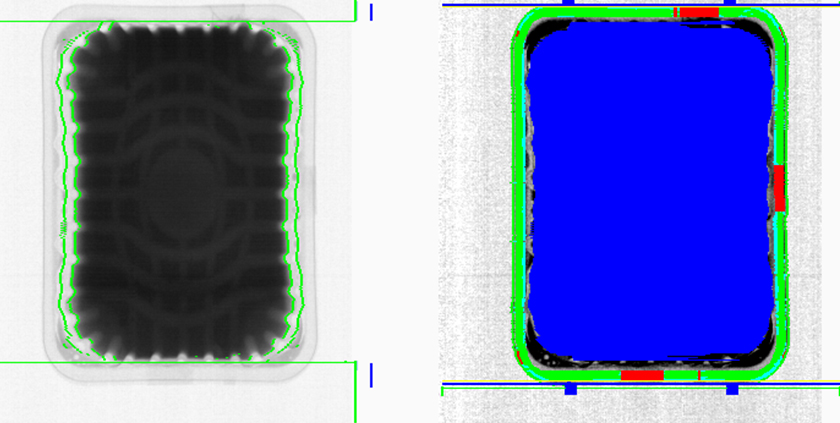

Our seal inspection technology offers unrivalled accuracy which improves product shelf-life and minimises the risk of returns. It can detect even the tiniest speck of sauce trapped in the seal of a ready meal, for example. Our patented technology generates two images from a single detector; one optimised for the product and one for the seam area.

Unlike vision systems, X-ray seal inspection can cope with non-transparent packaging and items with pack colours that are all very similar. And the addition of the seal-inspection option doesn’t increase the footprint of our G20 on the factory floor (apart from perhaps an extra reject bin). It also avoids the extra energy and manpower requirements of a separate seal inspection machine.

Of course, our patented seal inspection technology is not just for food packaging. We can also give the seal of approval to pharmaceuticals and cosmetics. Or get in touch to discuss bespoke x-ray inspection solutions.

Find Out More…

Sapphire SAC will be demonstrating our X-ray technology at Pack Expo 2021 on 27-29 September at the Las Vegas Convention Center in the US. Find us on Scan American Corporation’s booth SI-7466.

Alternatively, contact us for more information.